CNC (computer numerical control) processing is a high-precision, high-efficiency manufacturing technology that is widely used in aerospace, automobiles, medical equipment and other fields. However, the cost of CNC machining is affected by many factors, and understanding these factors is crucial to optimizing production and controlling costs. This article will delve into the main factors that affect CNC machining costs.

1. Material cost

Material cost is one of the most significant parts of CNC machining costs. Prices vary widely for different materials such as aluminum, steel, stainless steel, and titanium. The choice of materials not only affects the cost of raw materials, but also affects the difficulty and time of processing. For example, although titanium is high in strength and light in weight, it is difficult to process and the tools wear out quickly, leading to increased processing costs.

2. Design complexity

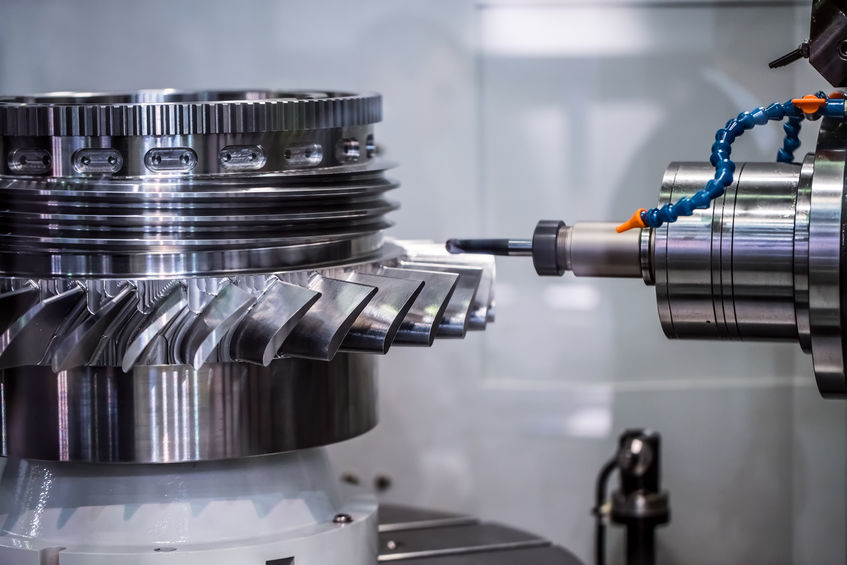

The design complexity of the part directly affects the cost of CNC machining. Complex geometries and fine details require more processing steps and time. Additionally, complex designs may require multi-axis CNC machines, which are expensive to use. Therefore, optimizing the design to simplify the processing steps can effectively reduce costs.

3. Processing time

Machining time is one of the key factors affecting CNC machining costs. The longer the processing time, the higher the cost. Machining time is affected by several factors, including cutting speed, feed rate and tool path optimization. By optimizing machining parameters and paths, machining time can be significantly reduced, thereby reducing costs.

4. Tool cost

Tool costs include the purchase, maintenance and replacement of tools. Different materials and processing requirements require different types of tools. For example, machining hard materials requires high-performance tools, which cost more. In addition, tool wear and replacement frequency also affect costs. Selecting appropriate tool materials and optimizing tool service life are important means of controlling costs.

5. Equipment cost

The purchase and maintenance costs of CNC machine tools are also important factors affecting processing costs. High-precision, high-performance CNC machine tools are expensive, but their processing efficiency and precision are high, which can reduce scrap rates and rework costs. In addition, equipment maintenance and upkeep is also a long-term cost. Regular maintenance can extend the life of the equipment and reduce the failure rate.

6. Labor costs

Although CNC processing is highly automated, it still requires professional and technical personnel for programming, operation and maintenance. The salary and training costs of technicians are also factors that affect processing costs. Improving the skill level and work efficiency of operators can effectively reduce labor costs.

7. Production batch size

Production batch size has a significant impact on CNC machining costs. High-volume production can spread fixed costs, such as programming and setup costs, thus reducing unit cost. On the contrary, the unit cost of small batch production is higher. Therefore, rationally arranging production batches and optimizing production plans can effectively control costs.

There are various factors that affect CNC machining costs, including material cost, design complexity, processing time, tool cost, equipment cost, labor cost and production batch size. By comprehensively considering these factors and optimizing the design and processing technology, CNC processing costs can be effectively reduced and production efficiency and competitiveness improved.