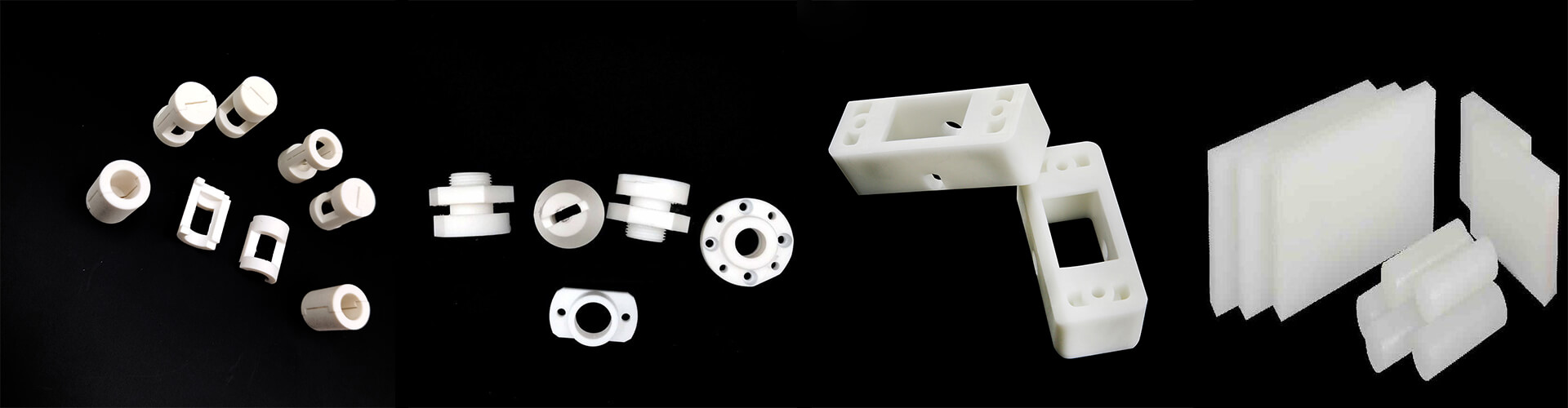

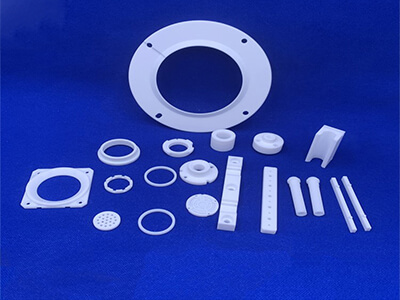

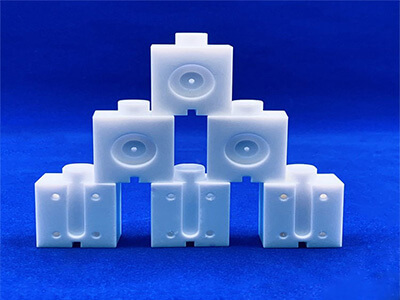

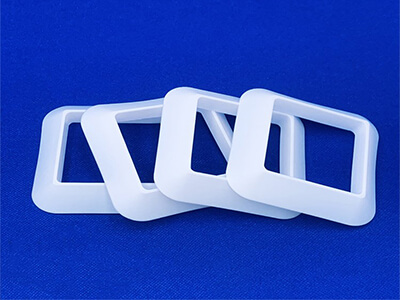

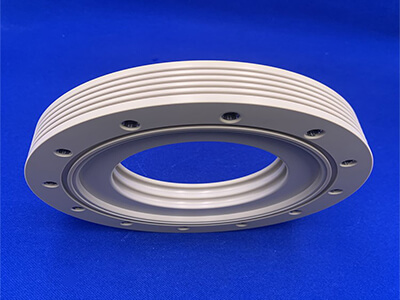

Fluoropolymer Machining

Fluoropolymers play an increasingly important role in industries such as construction, IT, and automobiles due to their excellent self-flaming retardant, self-cleaning, corrosion resistance, and high temperature resistance. In some fields, they have even become the most popular choice for users. Best choice.

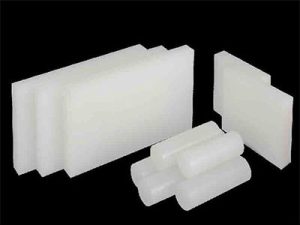

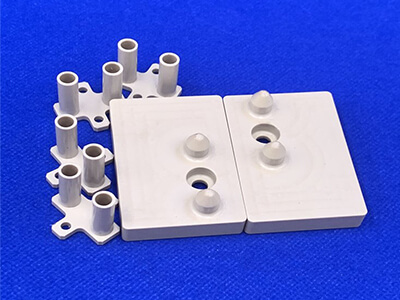

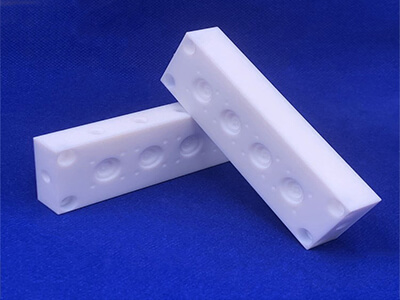

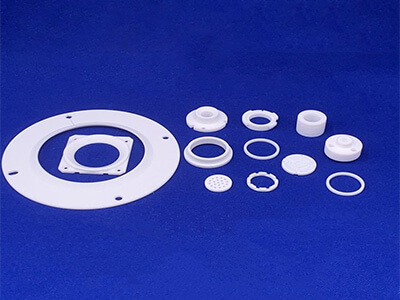

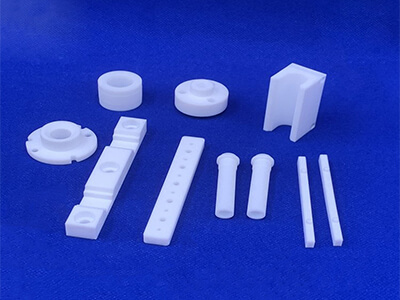

Fluoropolymer is a linear alkane polymer in which some or all of the hydrogen atoms in its molecular structure are replaced by fluorine. Fluoropolymers have very high chemical resistance, barrier properties, high temperature resistance and good electrical properties. They do not absorb moisture, have extremely low coefficient of friction, and have good weather resistance. These properties of fluoropolymers make them the material of choice for products such as heat-resistant cables, chemical-resistant liners, gaskets, pipes, filters, valves, pumps and electronic components, cladding materials, and weather-resistant films.