4 Axis & 5 Axis CNC Machining

WSF has 12 4-axis CNC machines and 3 5-axis CNC machines. Our 4-axis and 5-axis milling capabilities enable us to provide precision parts with complex geometries.

WSF has the ability to provide the best 5-axis machined parts. Our experienced team and manufacturing capabilities facilitate the rapid design and manufacture of complex, time-sensitive assemblies.

Get Free QuoteMain processing materials

Imported domestic carbon steel, mold steel, manganese steel, alloy steel, tool steel, high-speed steel, 304, 316, 303, 400 series stainless steel, aluminum alloy, copper, iron, aluminum parts, steel, ABS, plexiglass, PC, POM, PVC, PP, nylon, bakelite, plastic, Teflon, fluoroplastic, PTFE, PEEK, PI, PAI and other materials!

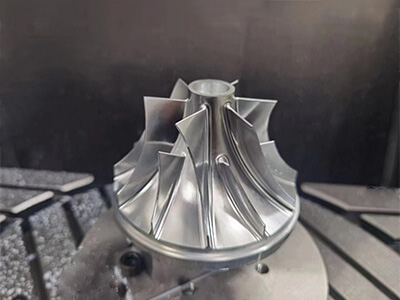

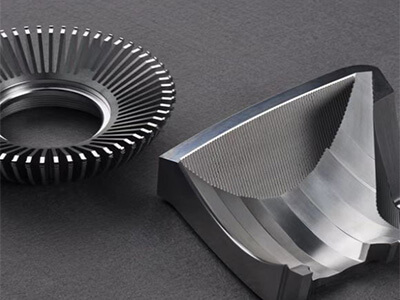

What Is 5 Axis Machining?

This type of machining relies on a tool moving in five different directions around which the tool rotates. It is a multi-axis subtractive manufacturing process in which the machine shapes the workpiece material and moves in 5 directions or vertically.

The directions of movement include; X, Y, and Z, as well as A and B. 5-axis machining allows operators to approach part machining from all directions and axis in a single operation. Therefore, eliminating the need for manual workpiece repositioning between operations. Also, it saves time and is ideal for creating highly complex parts requiring precision.

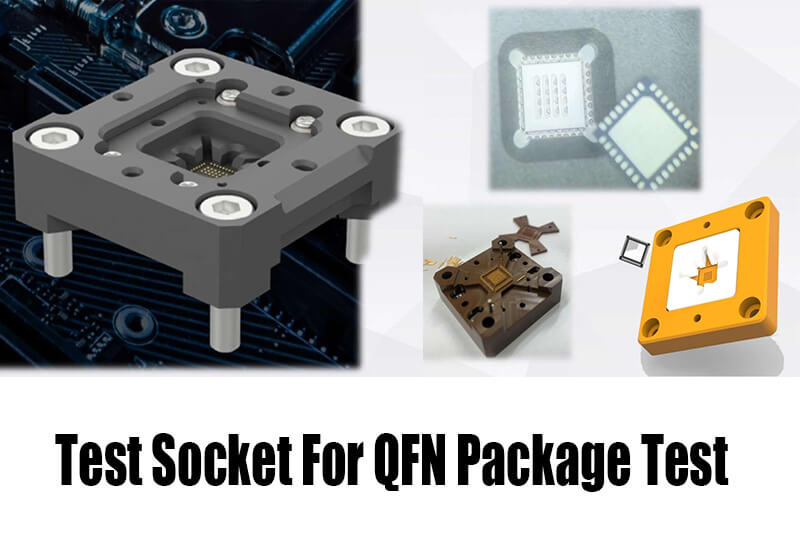

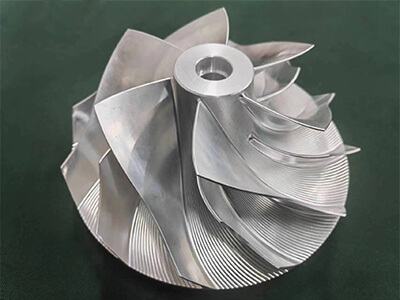

Latest Cases

WSF has 12 4-axis CNC machines and 3 5-axis CNC machines. Our 4-axis and 5-axis milling capabilities enable us to provide precision parts with complex geometries.

Features Of CNC Machining Services in WSF

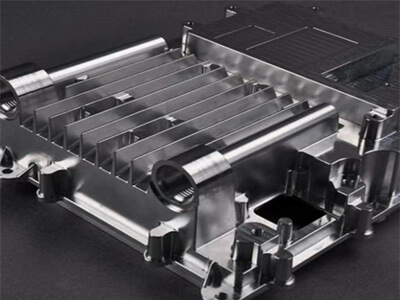

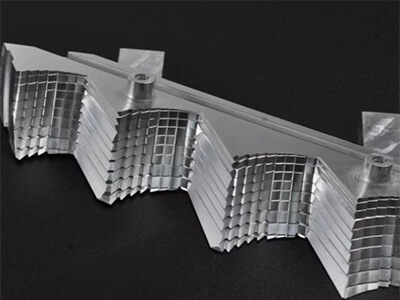

5 Axis CNC machining services at WSF have many advantages for product development that can make it the ideal solution not only for rapid prototyping but also for volume production. Here is what you should consider:

- Easily customized

- Versatile

- Fast turnaround

- Excellent surface finishes

- Highly accurate and repeatable

- Excellent for making complex geometries

- Suitable for many different kinds of substratest

- Scalable volumes from one to 100,000

- Low investment in tooling and preparation cost

- Parts are full-strength and can be put into service immediately

- Quick removal of large amounts of metal as well as engineering-grade plastic resins