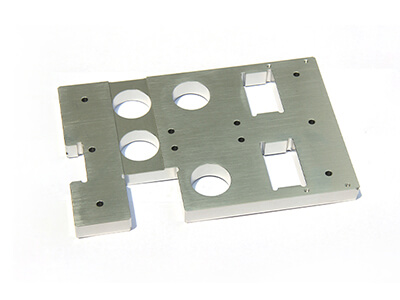

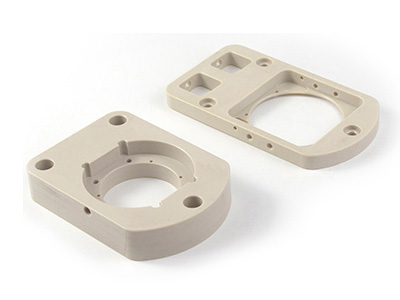

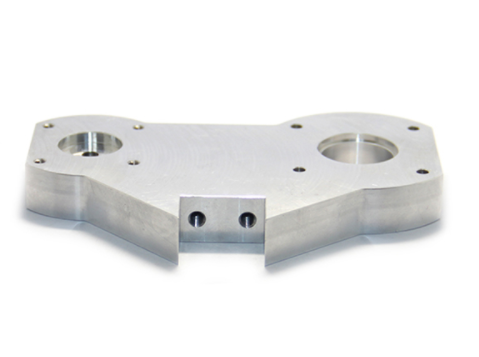

CNC Milling

CNC Milling is the process of cutting and drilling material (like plastic or metal). A milling machine, regardless of whether it’s operated manually or through CNC, uses a rotating cylindrical tool called a milling cutter. It is held in a spindle and can vary in form and size. The main difference between a milling machine and any other drilling machine is the ability to cut at different angles and move along different axes. Various complex parts can be processed quickly.

Get Free Quote