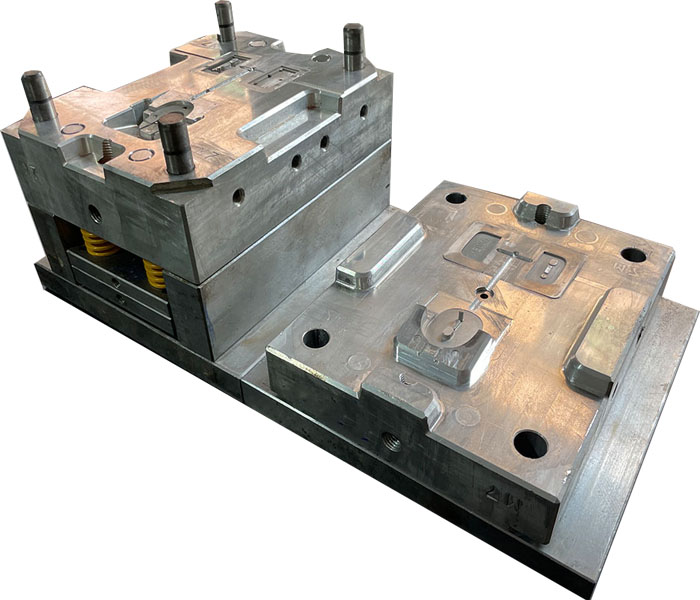

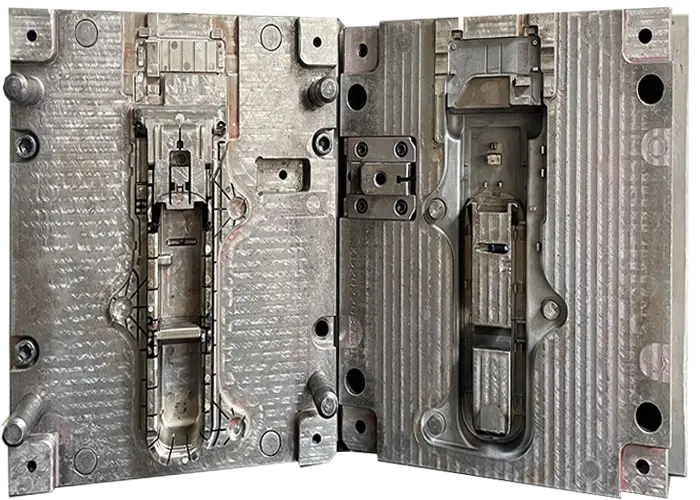

Rapid Tooling

Rapid Tooling is to quick make a low cost prototype mold and use the mold to get hundreds to thousands molded parts. A rapid tool should have some below features.

We are also your best low volume manufacturing partner. WSF is a leading rapid tooling & rapid injection molding manufacturer in China. We make aluminum 7075 & soft steel P20 molds inserted our reused universal or MUD mold bases that a rapid mold is done as fast as 5-7 days, meanwhile, 30%-40% cost saved than traditional production tools.

Get Free QuoteRapid Tooling China

WSF is a leading manufacturer in Rapid Tooling & Molding in China. With 10+ years experience and 300+ rapid molds per year, we could always provide our client best rapid tooling & molding solutions as below features.

- 5-7 days rapid tooling lead time

- 1-2 days rapid molding lead time

- 40% cost saved than traditional production molds

- 20% cheaper than China competitors

- 40% cheaper than western competitors

- 95% -100% quality equal to traditional molded parts

Materials of Rapid Tooling

At WSF, we always use S50C carbon steel (1.1730 or 45#) for the mold base. Regarding to the cavity/core, in WSF’s experience, the most used materials are AL7075 & P20, while there are several materials depending on different requests.

Materials of Rapid Molding

Generally, plastic materials that can be used to production injection molding can also be molded from a rapid mold. Below are the most common molded plastics. If the material is not listed, please contact our team for more information.

- ABS

- ABS/PC

- Nylon

- PP

- POM

- PS

- HDPE

- PA66+40%GF

- PET

- PETG

- PPS

- PPE/PS

- TPU

- TPE