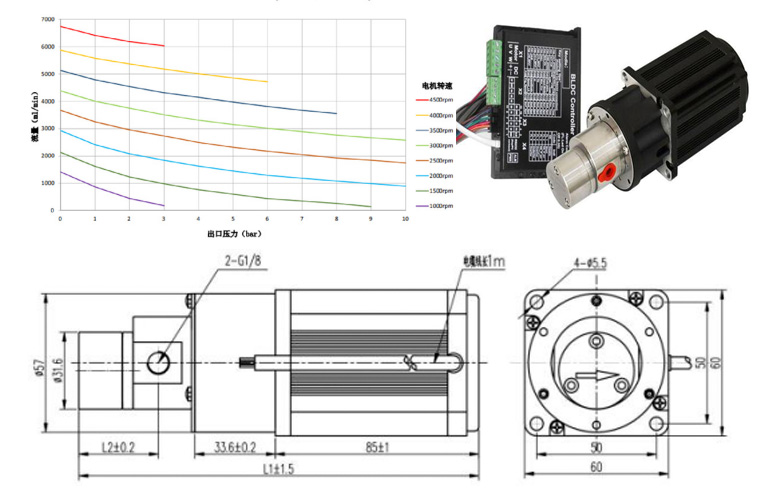

External Drive Gear Pump

A brushless DC motor is used to power the gear pump. It is equipped with a brushless motor driver to realize motor function control. It has speed measurement, adjustable rotation speed and forward and reverse functions. It can realize intelligent control by connecting with the host computer. It is especially suitable for workplaces with frequent starts and stops, such as precise liquid canning.