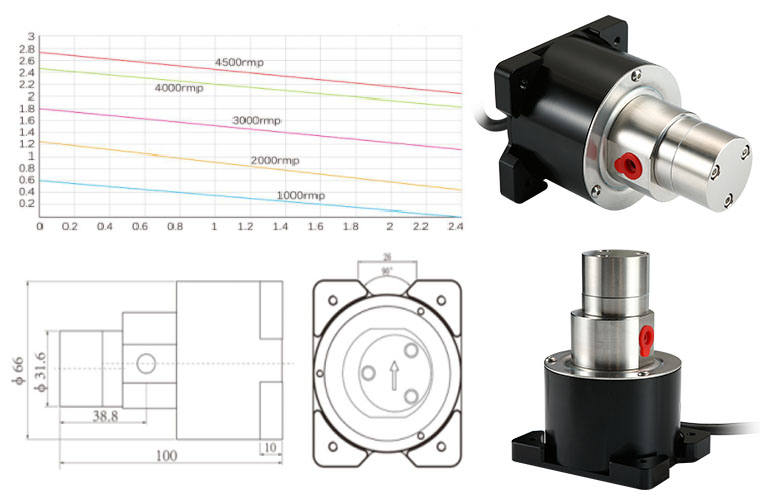

Magnetic Gear Pumps

The magnetic gear pump adopts the fluid transportation principle composed of DC brushless motor drive, micro stainless steel pump head and micro motor. It is especially suitable for various liquid media (acid-base, corrosion-resistant, toxic, flammable and explosive) within a small flow range. , hydraulic oil) transportation, dripping, sampling, circulation, diversion, spraying, flushing, filling, cooling and lubrication, water and air mixed gas, etc.