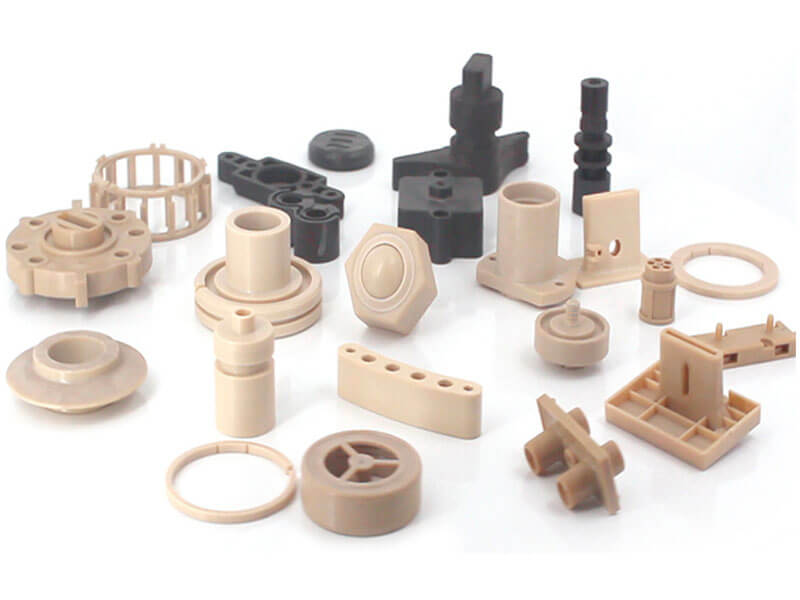

The density of pure PEEK resin sheet is 1.3g/cm3, which means that the weight per cubic centimeter is about 1.3 grams. PEEK is a special engineering plastic with many excellent properties, such as high temperature resistance, self-lubrication, easy processing and high mechanical strength. This material can be used to manufacture and process various mechanical parts, such as automotive gears, medical equipment, aerospace, etc.

If glass fiber, carbon fiber or HPV (graphite, carbon fiber, PTFE) is added to the PEEK material, its density will rise to about 1.45g/cm3. This is because the addition of these reinforcing materials increases the weight and volume of the material. PEEK sheet has the following characteristics:

1. The injection molding shrinkage of PEEK plastic raw materials is small, which makes it easier to control the dimensional tolerance range of PEEK injection molded parts, so that the dimensional accuracy of PEEK parts is much higher than that of other materials.

2. Small thermal expansion coefficient. This means that the size of the part changes very little with changes in temperature (whether it is changes in ambient temperature or heat generated by friction during operation).

3. Good dimensional stability. The dimensional stability of engineering plastics refers to the curling of the chain segments to a certain extent due to the increase in the activation energy of the polymer molecules during use or storage.

4. PEEK has outstanding resistance to thermal hydrolysis. Even in high temperature and high humidity environments, its water absorption rate is very low. It will not absorb water like other general plastics and cause significant changes in size.