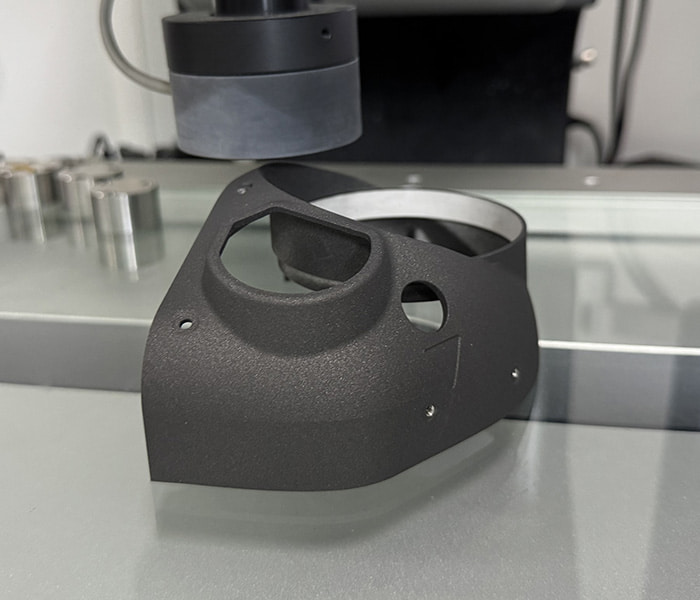

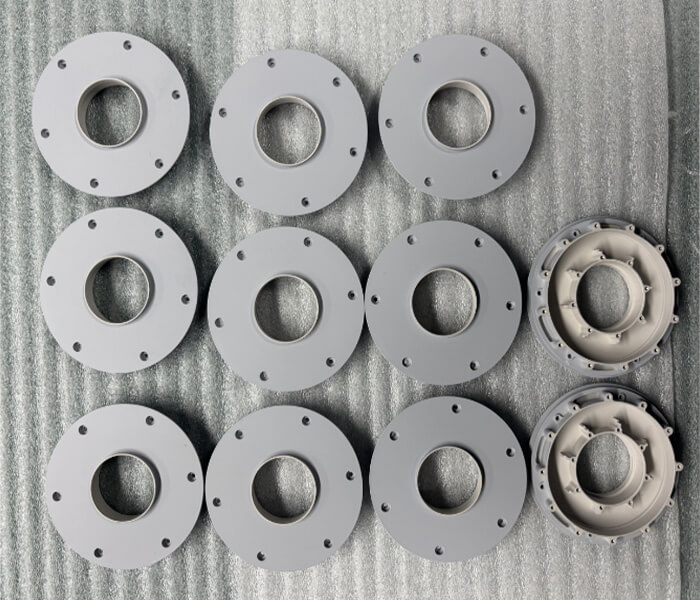

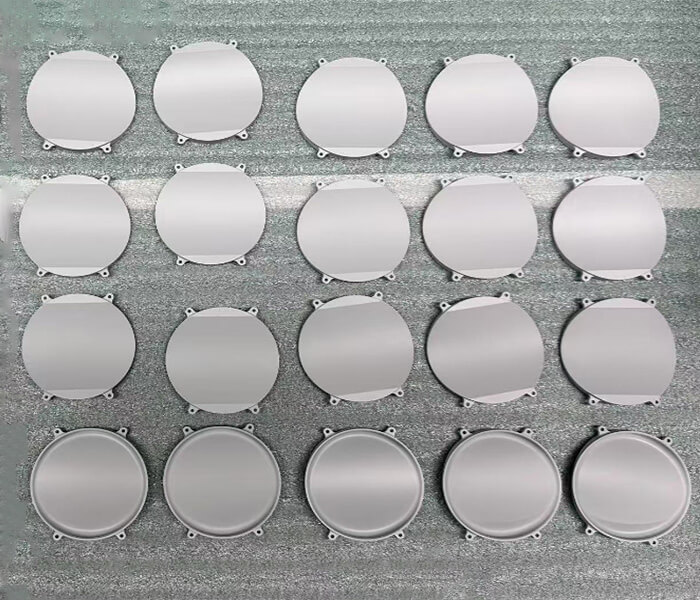

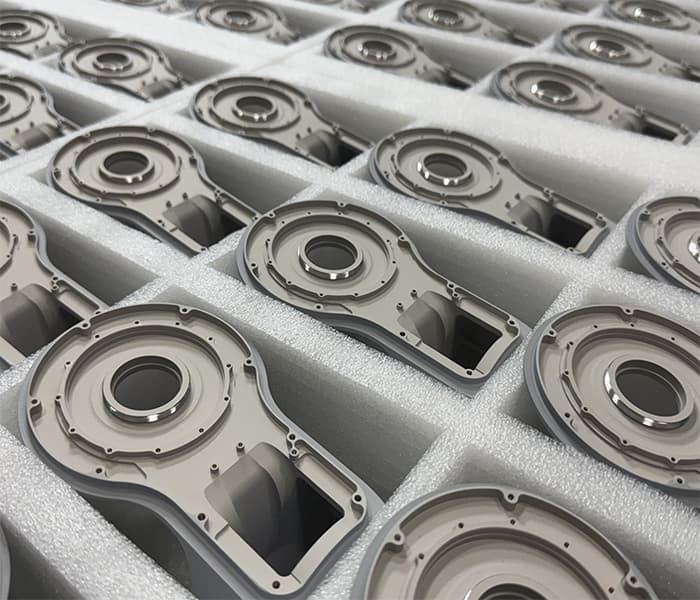

Magnesium CNC Machining

Magnesium is increasingly popular for CNC machining becaust it is lightweight and highly machinable in terms of feed rates. Machined magnesium also produces excellent surface finishes due to shorter chips being produced during the machining process. WSF offers multiple Magnesium alloys: AZ31-TP, AZ61B, AZ91D and AZ31B. Each has slightly different properties, but AZ31B is the most commonly used in CNC machining.

Get Free Quote