PEEK Machining

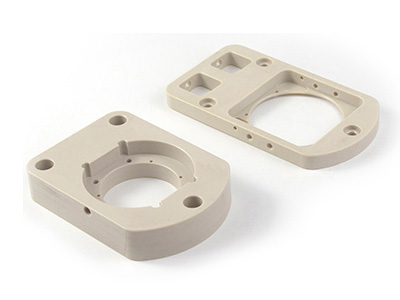

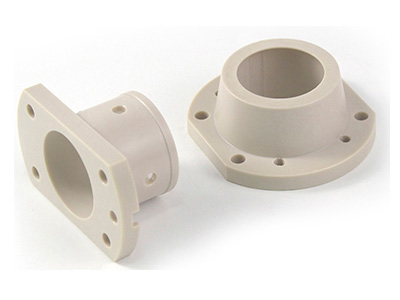

PEEK is a special engineering plastic with excellent performance. Compared with other special engineering plastics, PEEK has many significant advantages. PEEK has high temperature resistance, excellent mechanical properties, good self-lubrication, chemical corrosion resistance, flame retardancy, peeling resistance, With excellent properties such as radiation resistance, stable insulation, hydrolysis resistance and easy processing, it can be used to manufacture and process various mechanical parts, such as automobile gears, oil screens, shift starters, aircraft engine parts, automatic washing machine wheels, Medical device parts, etc., are used in aerospace, automobile manufacturing, electronic and electrical, medical and food processing fields. WSF’s technological development and breakthroughs in PEEK processing not only meet domestic production needs, domestically produced PEEK materials and products are also exported to foreign countries, breaking foreign technology monopoly. The technological innovation of PEEK materials has changed the disadvantages of traditional processing methods such as low utilization rate, high cost, and difficulty in directly forming complex structures, and has achieved low-cost, high-precision shape control and rapid manufacturing of high-performance PEEK materials. PEEK incorporates many excellent properties, so the PEEK application market is constantly being developed and innovated.