Rapid Tooling

Rapid Tooling is to quick make a low cost prototype mold and use the mold to get hundreds to thousands molded parts. A rapid tool should have some below features.

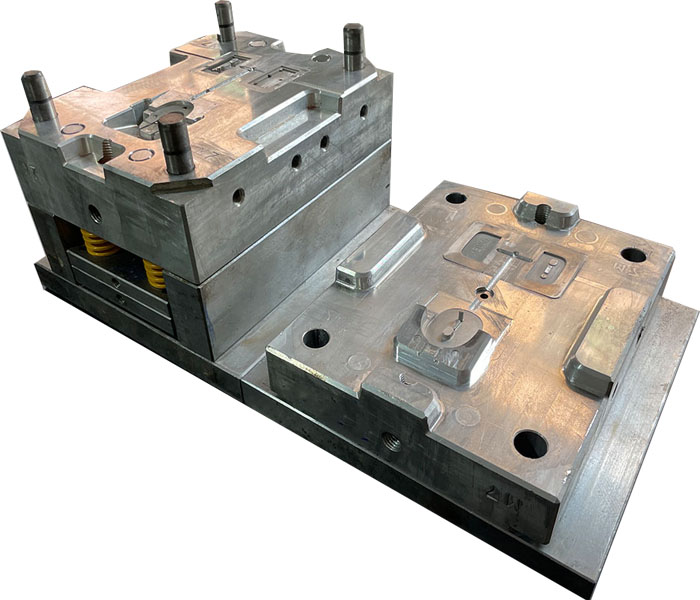

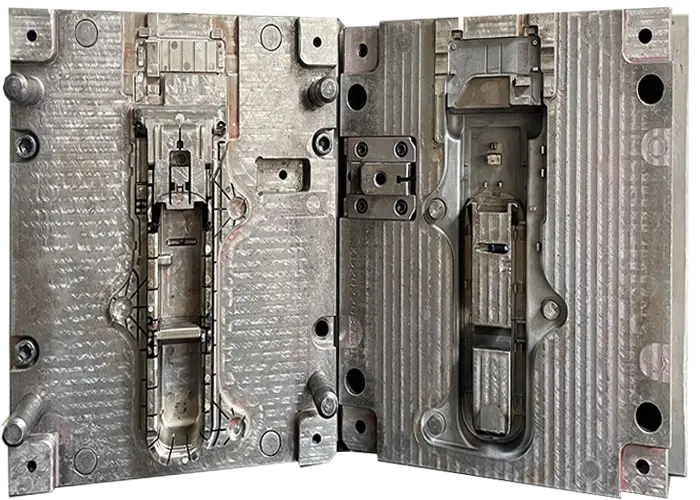

We are also your best low volume manufacturing partner. WSF is a leading rapid tooling & rapid injection molding manufacturer in China. We make aluminum 7075 & soft steel P20 molds inserted our reused universal or MUD mold bases that a rapid mold is done as fast as 5-7 days, meanwhile, 30%-40% cost saved than traditional production tools.

Get Free Quote